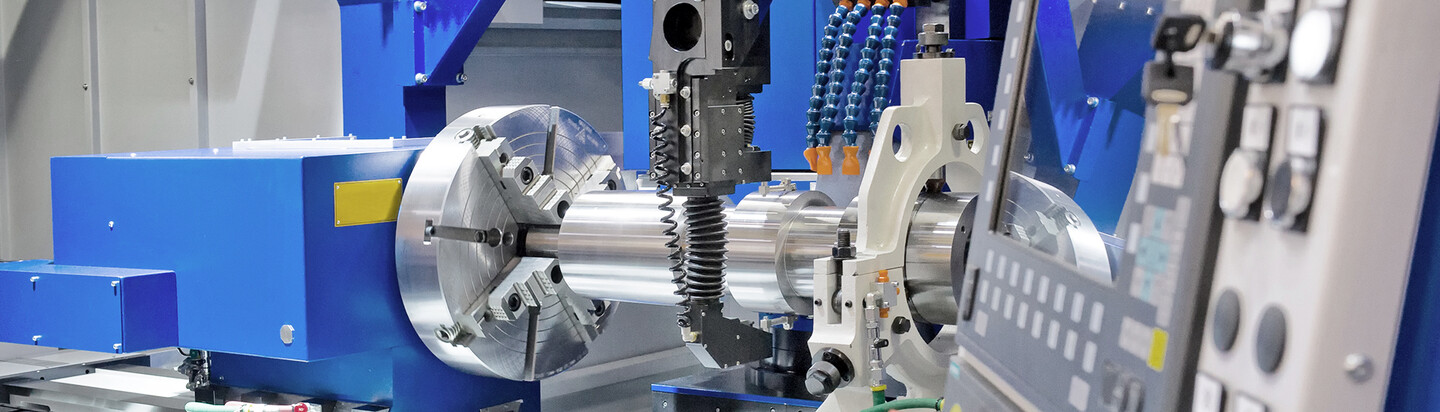

Mechanical engineering – we automate processes

Mechanical engineering mechanises operations that need to be performed with a high degree of accuracy, high repeat rates or in extreme conditions with extreme cost pressure. These challenges can affect the range of very different processes involved in a wide variety of segments. Our experienced team of electrical engineers and technicians work in the mechanical engineering segment in a solutions-oriented manner and cover almost every machine sector, including hydraulic steel construction, crane construction, packaging, production and logistics.

Programmed machine intelligence

In order to improve the efficiency of the machine, relieve employees from dangerous and strenuous tasks and reduce costs, technical systems are automated and equipped with complex measuring and control technology. This is where our engineers come into play. As experts in electrical engineering, measuring and control technology, PLC programming and process visualisation, we guarantee the safe and isochronous operation of your machines coupled with maximum throughput and availability. Our handling of numerous projects gives us the experience to synchronise drive axes and time sequences so that we can optimise your machines in this regard as well. Components manufacturers play a subordinate role for us here, because we already work successfully with products from Siemens, Rockwell, Wago, Schneider, Beckhoff, SEW and Lenze.

Solutions to interface problems

We are capable of fulfilling the most varied range of tasks stretching from electrical design to software programming and you can always rely on our expertise. You also get to benefit from our long-term experience with interfaces of various internal control and ERP systems such as SAP. Interfaces also play a key role in product handling. The resulting data is passed from machine to machine throughout the process. We know what to look for in this regard, are familiar with the challenges that can arise and know how to deal with the corresponding interfaces to achieve clean data processing.

Retrofit for your system

It goes without saying that the modernisation and expansion of existing systems belongs to our portfolio of services. We upgrade drives, control technology, sensors and visualisation to the state of the art and optimise processes while retaining the existing mechanics. By doing so, we cost-effectively expand the system for the future and increase the performance at the same time.

Our services

- Functional analysis

- Optimisation of processes and interfaces

- Error-free data handling across different interfaces and manufacturers

- Electrical planning and documentation

- Electrical design

- PLC programming

-

Handling machines (robots)

-

Packaging machines

-

Bagging systems

-

Cranes

-

Automated crane systems

-

SAP interfaces for orders, production data reports

-

Connection to ERP and material management systems in general

-

- Visualisation of production processes and process controls

- System optimisation and cost savings

- Customised automation solutions

Cross-sector and manufacturer-independent experience in the automation and modernisation of machines is something that sets us apart. Our know-how also makes it possible for us to successfully exchange data between different machine types. Present your project to us and benefit from our knowledge in the field of electrical engineering and automation.