DEK northern route: new construction of 5 locks, electrical engineering

Starting position

The Dortmund-Ems Canal is an artificially created waterway that links the Ruhr area with the North Sea. The canal was opened in 1899 and was 265 km long, 30 m wide and 2.5 m deep at the time. 16 locks and lifts were used to overcome the 70 m height difference along the route. The Dortmund-Ems Canal is divided into a southern and northern route. The southern part of the northern route contains the "Rheine lock staircase" which consists of six locks and overcomes a height difference of 29 m over a length of 29 km. As there was a shortage of water in this area at the time, the locks were built very small. After just a few years, they were no longer able to cope with the number of ships passing, so larger locks were built. These newer and larger systems are now over 100 years old and not designed to accommodate today's standard ship sizes. Altenrheine lock was converted back in 1974 to enable modern ship types to enter it. This meant that the remaining five locks (Bevergern, Rodde, Venhaus, Hesselte and Gleesen) formed a bottleneck and forced large ships to take a diversion of several hundred kilometres. Owing to their small size and old age, they are now to be replaced by 5 new, larger locks, each with a basin length of 140 m and basin width of 12.5 m.

The Task

The construction of the five new locks means that the Dortmund-Ems Canal will be navigable throughout for large inland cargo vessels (LICV) and, at the same time, will be equipped for a possible next expansion stage for oversized inland cargo vessels (oICV).

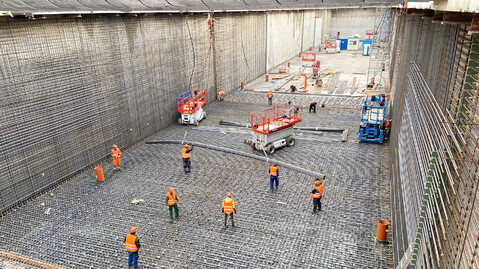

The presence of a large number of locks in a limited space means that large quantities of water are moved downwards in the canal through the lock stairs. To ensure that sufficient water is available in all sections, making safe navigation possible, an open water pipeline is to be built at all five new locks. Owing to the large lifting heights of 8.1 and 6.37 metres respectively, the Bevergern and Gleesen locks will be equipped with several economising basins. Economising here means that some of the used water can be collected and reused. The lifting heights of the two locks are also the reason why these two lock basins are built in a solid construction, whereas the other three lock basins are built using sheet piling.

The locks are controlled from the control centre in Bergeshövede, but for emergencies they still have a local control station. In order to make use of planning synergies and reduce production and maintenance costs they will, as far as possible, be designed and equipped technically in the same way, despite the five locks having very different lifting heights (Bevergern: 8.1 m; Rodde: 3.8 m; Venhaus: 3.5 m; Hesselte: 3.36 m; Gleesen: 6.37 m).

Since the beginning of the project, the "DEK-Nord – Schleusen" engineering association has been providing planning services for object and structural planning along with technical equipment. In addition, health and safety plans, a hazard analysis and concepts for fire, lightning, surge and burglary protection are also being created and a 3D simulation developed.

Services

At the beginning of the project, an assessment of the demand for the electrical power required was performed so that the grid operator can provide the required amount of energy for the facility in time. We also planning a transformer station, low-voltage distributions and sub-distributions, the cable network and a sophisticated route system for each lock system in order to supply all the consumers with the required amount of power systematically. A lighting calculation was also carried out to determine the lighting required for the lock, the outer harbours and the operational terrain. Part of our assignment also includes the development of an earthing and lightning protection concept to protect terrain, buildings, electrical equipment and people from the consequences of lightning strikes.

Two operation buildings exist at each of the five lock systems - one at the lower head and the other at the upper head. The technical building equipment, including ventilation, cooling and photovoltaic systems are planned for this purpose. The control technology for each lock and the connection to the control technology for the remote control from Bergeshövede will also be designed, while a risk assessment according to the Machinery Directive will performed and sample operating instructions prepared.

Over and above this, an energy optimisation study was performed and an examination made of which measures can save energy so that all the valid standards and regulations continue to be complied with. An estimate of the operating costs for the planned installation for each lock location was also performed.

A 3D simulation model of the Gleesen lock was created in order to be able carry out preliminary tests of the control technology and as a basis for training. Furthermore, a CCP system (CCP = cathodic corrosion protection) was planned and dimensioned for each of the three locks in sheet pile wall construction (Rodde, Venhaus, Hesselte) in order to protect the sheet piles against corrosion.

Challenges and special features

The inland shipping sector does not permit every ship to take a detour because certain locks are closed for several months or even years owing to new construction or modernisation work. For this reason, the existing locks need to continue to be operated safely during the entire construction phase, which places high demands on the planning community and entails a number of provisional arrangements. In order to make sure the project keeps within the time frame, several lock sites are also being worked on in parallel, but in different phases of planning.