Replacement construction of the Steinhavel weir

Initial situation

The Steinhavel weir consists of a lock facility built in 1840 and renovated in 1967, along with two weir systems: the Mühlenwehr and the Freiarchenwehr. It forms part of the Upper Havel Waterway and is therefore a key element of the water connection between Berlin and the Müritz, as well as the Kammerkanal towards Neustrelitz. The lock is passed by more than 24,000 vessels annually, mostly leisure boats. All structures of the weir were in poor condition and were therefore restored through replacement construction.

Objective

The replacement construction included the lock facility with its operating building and the expansion of the outer harbours, the weir system, the boat haulage and the access routes. As part of this modernisation, the facilities were to be automated and the conditions for navigation and lock operation improved. The lock and weir were also connected to the control centre in Zehdenick, enabling remote support for the user-operated lock when necessary. To ensure ecological continuity, a fish pass was also constructed.

The cross-structure planning of the technical equipment for the entire weir and the operating building was carried out by DriveCon.

Services

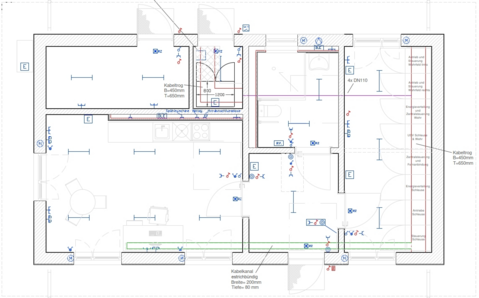

The power supply for the entire facility is provided from the local energy supplier’s low-voltage network and via a new low-voltage main distribution board in the operating building. Separate sub-distributions were planned for all drives of the lock and the weir system. In addition, a connection point for a mobile emergency power generator was created in the technical room to ensure that the drive systems and other key components can continue to operate in the event of a power failure. Furthermore, an uninterruptible power supply (UPS) system with a capacity of 10 kVA was included to maintain complex electronic systems.

All mitre gates, valves and fish-belly flap gates are powered by electric lifting cylinders, with motors controlled via frequency converters. The control technology for the lock, the weir and the fish pass was also planned, including the preparation of the necessary schematic diagrams. In addition, the communication and control technology was designed in the form of an operator and monitoring system, including the connection to the Zehdenick control centre. Together with the video, sound and intercom system, this setup allows for assistance during user-operated lock operations in case of problems and enables monitoring of the automatically controlled weir system if required. The planning also included entrance monitoring, a traffic light system, a level gauge and gate chamber monitoring.

A lighting calculation was prepared for the lock facility, including the outer harbours and the access routes. Furthermore, the complete building installation for the operating building was planned, covering energy distribution, lighting, power sockets, ventilation, air conditioning and heating systems. Key tasks also included the development of a concept for lightning and surge protection, as well as the planning of the earthing system and potential equalisation. In addition, a risk assessment according to the Machinery Directive was conducted.

Challenges and special features

As part of the project, all existing lines were completely removed. To ensure continuous supply to the former operating building during the construction phase, a temporary cable routing was established over the upper outer harbour.

A significant challenge arose due to the project’s location in a protected landscape area. This restriction considerably influenced the planning of routes and technical equipment in the outer harbours. The protection regulations severely limited the available space along the shoreline for the implementation of routes and technical installations.

To connect the lower outer harbour, empty conduits were laid beneath the waterbody using directional drilling. This method minimised the environmental impact while meeting the structural requirements.