Sophisticated control logic for optimised warehouse and conveyor logistics

The shipment of goods and automated transportation in the production chain make up a key part of our everyday working lives these days to ensure that the goods ordered are delivered quickly and efficiently. For this reason, ever-increasing demands are being placed on intelligence, efficiency and reliability within intra-logistics.

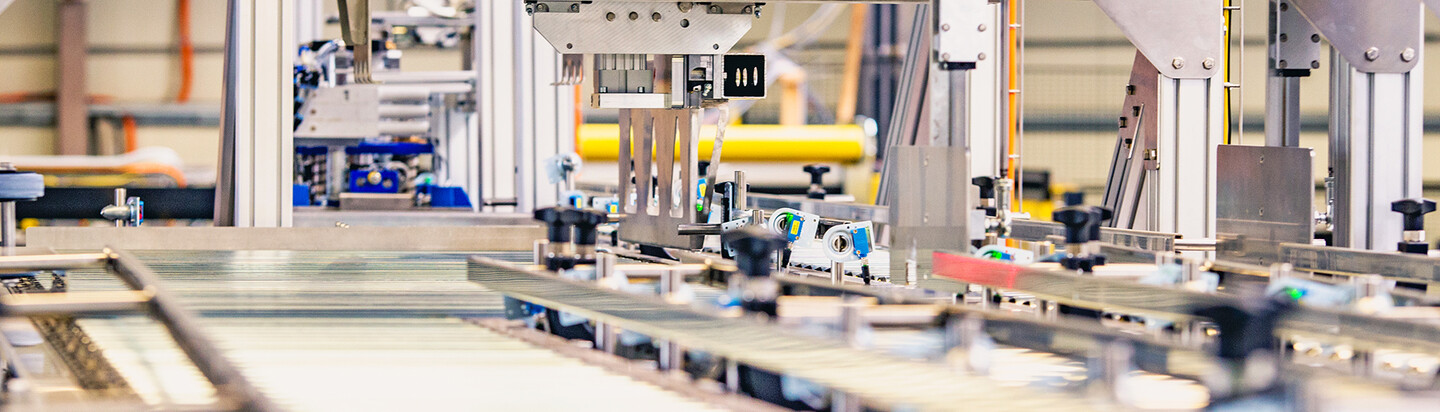

Automated warehouse and conveyor systems, for example, are of the utmost importance on production lines, enabling them to be resupplied or for the goods produced to be transported under defined and constantly consistent tolerances and conditions and stored for sale. Automated production lines, pallet conveyor systems and high-bay warehouses are used for these processes. Handling machines also take care of the packaging and other jobs. We use our software solutions to automate your warehouse and logistics system and optimise the flow of goods as a result.

Increasing efficiency through automation

At the heart of the system are powerful and highly available storage and conveyor technologies and programmable logic controllers in connection with material flow and host computers. In the modern logistics segment, therefore, all the machines communicate with the host computer over TCP/IP. This computer connects all the components and parameters and by doing so controls the movements of all the containers and pallets on a conveyor system and in the high-bay warehouse.

Our experts make sure that all the components installed from different manufacturers communicate without loss, synchronise interfaces and develop the PLC programmes required for the control technology. The analysis, evaluation, planning and optimisation of processes are part of the basic scope of services in a DriveCon project. This strategic approach allows us to successfully optimise production quotas, material flows, availability and efficiency and minimise congestion and downtimes. And we incorporate the new software into your existing IT and logistics system as a matter of course. We are also happy to rely on your software standards in order to ensure a uniform software image in the system.

Project experience in the warehousing and logistics segment

Our engineers and technicians have many years of experience in the logistics segment and a detailed understanding of its special requirements. We have acquired this knowledge from numerous projects in which we have, for example, programmed PLC software for storage and retrieval machines, pallet conveyor systems and container conveyor systems.

Highly complex logistics systems often make high demands on the PLC technology used. Our experience shows that some machines need axis movements to be time-optimised to make the processes as short as possible. In contrast, other machines require a large amount of data storage and handling of various type of additional information on the product being conveyed. What they all have in common, however, is that from the beginning until the end, i.e. from the incoming delivery to the shipment, the product data needs to pass through the system without being overwritten or lost. It does not matter to us how your product is transported or whether different load carriers are required for transportation. If the mechanisms can convey your goods, then our software can do it as well. In short, we develop intelligent software solutions for programmable logic controllers to increase the throughput and reliability of your system and in doing so reduce your costs in the long term.

Our services

- Automation of the warehouse and logistics system

- Optimisation of the flow of goods

- Software concepts

- PLC programming

-

Pallet conveyor systems

-

Container conveyor systems (small parts conveyor systems / SCS)

- Storage and retrieval units

-

Small parts stacker cranes

-

- System visualisation

- Analysis, evaluation, planning and optimisation of processes

- Solving challenges

- Loss-free data handling

- Tracking

- Experience with various conveyor systems and stacker cranes

- Cost reduction

- Software commissioning in Germany and abroad

Do you want to expand or optimise your existing fully automated warehouse? Then we guarantee the fast transport of all units and short access times with our control software. Convince yourself of our high level of knowledge and send us your project enquiry.